It’s been a year since we launched the Field Grey Sustainability Manifesto – a commitment to rethinking how uniforms are designed, made and worn. It wasn’t about flaunting our eco credentials, it was about setting real, actionable goals to reduce waste, make garments last longer and embed sustainability into every stage of our work.

Seeing Salvage magazine’s shocking images of dumped textiles – mountains of discarded clothing – was a wake-up call. It forced us to rethink our industry’s impact. At the same time, we realised we were already doing a lot of things right. We design brand apparel that’s built to last. In a world of over-consumption, that’s no small thing. But we knew we could do more. And so the Sustainability Manifesto was born.

Twelve months in, we’re taking stock of the progress we’ve made and the challenges ahead. Sustainability isn’t a badge of honour, it’s an ongoing process of learning, refining and doing better. The good news is we’ve taken some forward strides – pioneering circular fashion initiatives, cutting waste and sourcing more ethically. Here’s how we’re upholding our commitment and pushing for real change.

Making uniforms circular

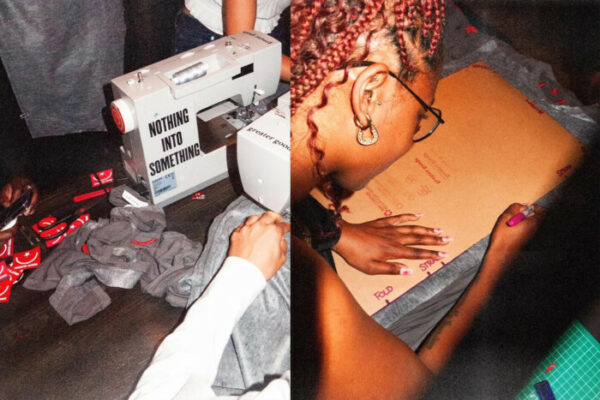

One inspiration behind the manifesto was the principle of more use per user – outlined in The Circular Economy by the Ellen MacArthur Foundation. A truly sustainable product is one that’s worn for longer. This means creating uniforms that can withstand years of use and that people actually want to wear. Then there’s more uses per product, making sure items aren’t ditched after one wearer. The explosion of resale platforms in recent years shows second-hand fashion is now mainstream. We took it a step further with our circular fashion initiative for Wagamama, in partnership with eco-brand Pangaia. Instead of tossing old uniforms, we reworked them into something new – proving that workwear can be circular, not disposable. It paves the way for a circular workwear philosophy and is one of the projects we’re most proud of.

Mindful design: beyond sustainable materials

People love to talk about “sustainable fabrics” like organic cotton or recycled polyester, but sustainability isn’t just about materials. It’s about what happens when those garments reach the end of their life. If they’re stitched with polyester thread, for example, it can be difficult to take them apart in order to make them fully circular. That’s why Mindful Design is the first point in our manifesto. Circularity goes beyond what a garment’s made from – it’s about how it’s built, repaired and eventually repurposed.

We’ve started embedding these conversations in our client proposals. When designing uniforms, we ask: What happens at the end of its life? Can it be refurbished? Can it be reissued to new staff? By shifting focus from just materials to the entire product lifecycle, we’re helping brands move from greenwashing to real action.

A key part of this is extended use. The fashion industry has perfected the art of planned obsolescence – designing garments that last just long enough to require replacement. We take the opposite approach, reinforcing stress points like pockets and crotch seams to extend a garment’s life. We use chain stitching in key areas for added strength – so much so that when we moved chino production to a factory without chain-stitch machinery, we worked closely with them to find an equally durable alternative. These small technical details make a big impact.

Cutting surplus, not corners

Fast fashion has normalised the idea that returns, deadstock and unsold items are just part of doing business. Some brands even make returns deliberately expensive, discouraging customers from sending items back. This leads to perfectly good clothing ending up in landfill.

For us, cutting waste starts with better production planning. Over the past year we’ve been working with a specialist grader, who makes sure our sustainable design intentions are backed up by our production process. Using precise digital lay plans means factories can cut fabric with little waste, so we produce only what we need. This makes good business sense too – using less fabric means we get more bang for our buck. But more importantly, it means we’re consuming fewer raw materials.

Producing in small batches has always been part of our model, but it’s getting harder. Factories that once allowed us to order 50 units now require a minimum of 100. Brexit has made working with European manufacturers more expensive and inflation has squeezed margins. But despite the challenges, we keep production runs small – compared with industry norms, our waste is minimal.

When surplus does arise, we find ways to rehome materials before resorting to the rubbish dump. We regularly donate excess fabric to universities, giving students access to high-quality textiles for their projects. It’s a simple step, but one that shifts the mindset from waste to reuse.

Ethical sourcing through direct relationships

Clients are asking more questions about ethical sourcing, which is a positive shift. But sustainability audits can be misleading – some are brilliant, while others are little more than tick-box exercises. A certificate doesn’t guarantee ethical practices. That’s why we believe in building direct relationships with our suppliers.

This year, we visited a key factory in Tunisia, with a trip to Portugal planned next. Being on the ground makes all the difference. It encourages accountability and means quality and ethical standards are genuinely upheld – not just written on paper.

Smarter uniform management

Sustainability is about making better, but also using smarter.

One of the biggest shifts this year is getting our clients to move towards a fully managed uniform service. This means when uniforms are needed for seasonal staff, for instance, they can be brought back in, dry-cleaned, stored centrally and then put back into stock. This means making fewer uniforms, keeping them in circulation longer and stopping them from vanishing into the lost uniform black hole – an all-too-common problem in large hotels.

Deadstock fabrics are another exciting area. During our visit to industry event Première Vision last year, we were impressed by the surge in deadstock options suitable for workwear, not just high fashion. We’re in the process of securing a strong deadstock supplier and are looking to incorporate their high quality fabrics into upcoming projects. Using what already exists is one of the simplest, most effective ways to reduce waste.

Real actions, not empty promises

One thing we’ve learned over the past year is that sustainability isn’t a checklist – it’s a constant process of improvement.

Big brands can measure their carbon footprint down to the decimal point, but sometimes you have to ask: Are they only measuring what they can account for? There’s a huge grey area.

For us, sustainability is about answerable actions – the tangible steps we can take within our scale and resources. That means formalising sustainability checks into our early conversations with clients. It means continuously evolving our approach to sourcing, production and waste reduction. And it means being honest about where we are, where we want to go and what’s actually possible.

One year in, we’re proud of the progress we’ve made. But we know sustainability isn’t a destination – it’s a journey. And we’re on the right track.

Read our Sustainability Manifesto here